Accelerating progress by moving from a traditional paper based system to a customized PTW software application

The Permit to work system is an important component when addressing safety. All industries (Oil & Gas, Construction projects, Chemicals, Hydrocarbon, Energy, Petrochemicals, Pharmaceuticals and others) are attempting to exercise PTW in a manner that is best suited to their operations. It is a crucial element in their overall adoption of safety standards and attempt to accomplish high safety performance.

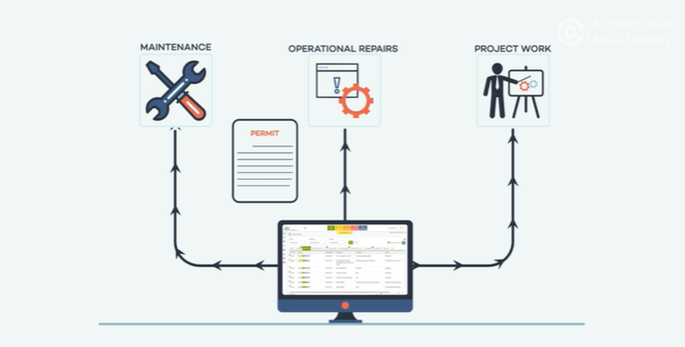

The attempt is to ensure that safety is achieved in their known routine activities like maintenance, planned & unplanned activities / repairs, emergency activities etc.The intention is to adopt standards that are being followed, lessons learnt (historical), learnings from past incidents and other general referential information. Through the use of the PTW system, there is a conscious and genuine effort being made to achieve and identify preventive measures that would allow them to avoid incidents.

In this attempt most organizations find it hard to keep up with the resulting work overload. This inadvertently delays their jobs / assignments, production and maintenance delivery timelines. The inevitable truth is that PTW is important but at the same time, production, maintenance and emergency assignments are also equally important. These are also required to be delivered inside given timelines.

People / Agencies that are involved in these activities are required to deliver timely results with appropriate and accurate reviews, assessments and validations. This might become a huge challenge for each of these agencies despite there being a conscious effort to implement these standardized protocols.

The PTW system also finds a significant mention in the newly established ISO 45001:2018 under clause 6.1.1. Here, it states the importance of PTW system and other recognition and control methods for improving OH&S performance (source: ISO website).Since most organizations are trying their best to comply with these standards, they do face stiff challenges along the way, like;

- Filling conventional paper based forms (usually in triplicate)

- Collecting permit requests and identify the appropriate authority for getting necessary approvals

- Ensuring accurate coordination between multiple persons / agencies

- Identifying the appropriate authorities for conducting physical safety checks and evaluations

- Universally, contractors make up for about 50% (or more) of any operational activities. To ensure that they completely understand an organization’s PTW system and adopt it to the fullest, is a big challenge. These contractors might hardly be aware of different authorities / hierarchical structure which they can follow and hence, wander aimlessly trying to figure out the appropriate authority who might be able to give them necessary approvals.

- A particular area authority might be perplexed by the number of activities that are prevalent in his sector. He might have no knowledge of whether there are permits that have been issued or not in his section. Sometimes they might have to physically check their sites to determine the number of permits that are ‘LIVE’ in their section, thereby, adding to their already existing delays in work.

- Organizations having multiple plants might also face a totally different challenge. Each of their plants might be following a different format / type of PTW considering geographical influences. Most plants might have evolved over a period of time and may have changed formats, work-flows and hierarchies. This leads to issues in reconciling data received from each plant with unique sets of data. This again might lead to challenges in ensuring that the standard system is being followed in the whole organization.

A business case for digitizing the PTW system

Digitally enabling your PTW system can provide you with a myriad of benefits that address each of the challenges that have been mentioned above. Here are the best 5 benefits that you might avail using PTW software;

1.Convenience in carrying out a PTW process

Using software, one is able to create templates, save drafts and share permit forms digitally. This results in a significant savings of time, effort and assets. When permit requests reach control centers, approving authorities and far reaching agencies quickly, approvals can also follow quickly and effectively. General human errors are minimized and at the same time, no approval by-pass’ are allowed, effectively cutting down any minute chances of mistakes.

2.A web based application – compatible with handheld devices

The beauty of web based applications are well documented. The idea is to identify the benefits vis-à-vis the operational processes of a PTW system and implement them to ensure optimum productivity.

3.Consistent and uniform process – Centralization through customization

Multiple plants from multiple geographies might require to follow uniform standards. With the software, organizational headquarters might be able to centralize data by adopting a centralized PTW system that is followed universally in all plants.

4.Operational effectiveness

One is able to achieve multiple operational benefits like increased efficiency in operations, increased ‘uptime’, reduction in operational costs, transparent coordination among multiple agencies, easy accessibility and effective interactions.

5.MIS & KPIs – Digital benefits

The obvious digital benefits that any organization might enjoy are quick (click ready) reports, ready references (empirical data of permits), data driven trends, data driven insights and lessons learnt from previous near misses / incidents. Data can also be represented graphically to management for review.

Much of these benefits have already been explained in a previous blog which you can refer to here: digitizing permit to work software

All-in-all, it can be safely said that digital upgradation of the PTW system is potentially the next big step that organizations might need to take for further strengthening their workplace safety.

Share your thoughts with us!