E-learnings for operators

In an industry, the contribution of operators is vital – be it overseeing the production, monitoring the output and its quality, they play an important role in carrying out the basic manufacturing processes. Though there are scheduled time-based PM (periodic maintenance) in every industry, it becomes difficult to effectively alleviate the risk of random failure scenarios. Mostly, it is the operators who are the closest to a process or an equipment, especially when it is operating in a stable mode.

In an industry, an operator’s mitigation capabilities benefit a strategy that is required to lower the risk in the value stream. They are a first line of defense against the effects of unmitigated risks, and through cross-functional collaboration, they can be in a perfect position to develop and test on-line routine tasks.

Today’s workforce is a combination of both – newer generation and experienced ones. Complex, highly automated production systems lead to different expectations about the technology, and the changing circumstances create an urgent need to improve the operator trainings. Any negligence to the same can cause serious implications.

To understand this better, here is a real scenario of events that occurred in a metal and plastic industry –

A die cast operator was working with an automated die cast system that utilized a Unimate robot. In one minute, it was programmed to perform the entire cycle – extract the casting from the die-cast machine, dip into the quench tank and insert into an automatic trim press. In afternoon, the operator entered the working area of the robot by walking through one of the unguarded gaps between the safety rail and related die-casting equipment. He had an air gun with him, and he went to clean up flash and scrap metal that accumulated on the floor (here, he was exposed to struck-by hazards, struck between objects, mechanical and electrical hazards).

Now, this was a prohibited activity and though the air hose was attached outside the work envelope, it was sufficiently long to allow the operator to clean up the floor anywhere inside the envelope.

The next thing was, a fellow employee heard an air hose steadily hissing. When he went to investigate the hissing noise, he discovered the operator pinned between the right rear of the robot and a safety pole in a slumped but upright position. He was declared dead.

The shift to e-learnings

The above incident could have been prevented – if there were specific trainings to help him identify symptoms and adverse conditions in his work-area.

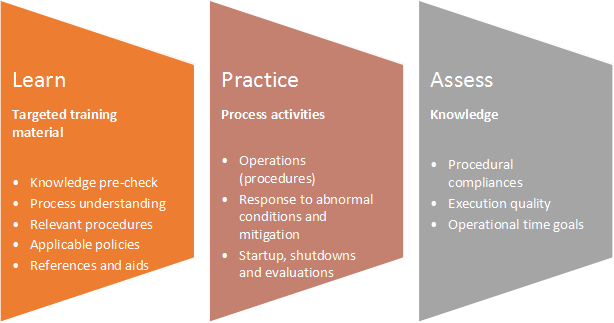

To cement training lessons effectively, immersive replication of the real-world scenarios is possible through e-learnings. At a field level, operators should be able to identify, rank and address the physical and process safety hazards that they might encounter. Learnings, when flexible and interactive, help them evaluate options while dealing with various categories of hazards.

With e-learnings, mobile, relevant, self-paced and personalized content is possible; plus, it ensures increase in learning productivity amongst the industry personnel.

With the ubiquity of web-based digital learning, it helps in learning regresses, and supports them with dealing those challenges.

But, it is mostly observed that operators aren’t much tech-savvy (from the industry perspective) or highly educated. So, the E-learning environment can be designed in such a way that the learners can relate to those learnings. For eg. If the operators are to be trained to operate 50 machines, they can be categorized into some common characteristics and functions, so that they can easily recall the category.

Also, the simple use of language and real-life illustrations can give them a real feel, so that it becomes easy for them to recognize and operate those machines on-job. Sound effects similar to those machines can help – also 2D and 3D video animation can instill understandings in its best sense.

Performance-based learning objectives can involve the learners intellectually, physically and emotionally, and E-learnings pave the way for all three.