Job Safety Analysis – A Software Module That Assists Your Risk Assessment Initiatives

Have you ever fixed a bulb at home? What are the initial checks you perform?

- You check if the power supply is off.

- If the bulb is at a height, you check the stability of the ladder or stool.

- You even check if there is nothing around the ladder in case you fall, which can hurt.

- You wear rubber slippers, gloves, and other necessary PPE.

Post these checks; you perform the task of changing the bulb.

So imagine if a simple task like this needs that safety analysis; how much care, precaution, and vigilance would be needed when big, or small jobs are performed at a workplace? A workplace wherein the chances of injuries, incidents, and accidents vary invariably according to the nature of the tasks.

So, what is the first thing that comes to mind when you think or hear about job safety analysis? It is everything and anything that it takes to do any job safely. Therefore, right from ensuring that all the job specific PPEs are available and in great condition, necessary LOTOs are in place, all the work Permits requests are in made, the worker assigned th job is qualified and has been given proper training, so on and so forth, are the aspects required to be checked in a job safety analysis!

Although these examples sound simple, job safety analysis has much more to it than just analyzing the safety of the work. It has added layers to it to enhance and ensure the safety of every little step of the tasks at a workplace. Therefore be it corporate, industrial, or workshops, job safety analysis is a must.

To alleviate the effectiveness of job safety analysis, we have digital tools to identify, analyze and suggest control measures for a job to be done safely. Read on to learn more about how this tool can significantly change the job safety analysis of a workplace.

What is a Hazard?

A hazard is anything that can cause potential harm. Even tasks that can cause minor cuts, nicks, and bumps are a hazard. Therefore, a safety analysis tool is crucial to ensure 100% and 360-degree safety in every task at a workplace. A little ignorance can lead to harmful and dangerous incidents, accidents, and causal illness.

Noticing the minute hazards like not wearing proper PPE, unnoticed slippery surfaces, working at heights negligently, and more and taking immediate measures, can avert major incidents and prevent possible illness and injuries.

Why Is Job Safety Analysis Important?

Imagine a day at a construction site. The safety officer must check that all the day’s tasks are aligned safely. For that, they need to perform a safety analysis to ensure that any job does not interfere with the other functions, or SIMOPS as we know it, and that every task has a dedicated place and clear surroundings. They also must ensure that the people performing the jobs are trained and experienced. Post these checks and more, the officer can grant permission for the work to begin.

This sounds like an arduous task, right? However, everything must be done to prevent workplace injuries, illnesses, and incidents. JSA is also important as sometimes workers tend to go on autopilot mode. During these times, JSA becomes more critical. A proper JSA method has proved to reduce incidents considerably.

It shows that safety is the priority for every job. But it can sometimes be difficult for the safety team to amplify safety, perform safety analysis and get the job done correctly, as the safety officer needs to micromanage the task even before it begins, all at the same time.

But the JSA process can be tedious. It requires identifying the control measures and following procedures for approvals. Now, these tasks, when done manually, are very challenging. And the challenges add to the time for the job to be completed. Not to miss mentioning, having a load of paperwork making the tracking process all the more cumbersome. Therefore, it is essential to replace these age-old manual techniques with modern technology that effectively digitizes these processes..

What does the Job Safety Analysis Module Do?

A job safety analysis module crucially identifies, analyzes, and takes control measures for a job to be done safely.

JSA software makes it easy to analyze and mitigate job hazards. It provides amplified hazard identification and risk assessment of every task. It optimizes every task’s control to identify the most-suited control for job safety. And most importantly, it promises maximum adoption and ease of management.

Therefore a digital JSA tool;

- Proactively manages on-field and off-field activities.

- Works with multiple JSAs while referencing the previous ones.

- Provides ease of management.

- Scans through approvals of JSA in an instant.

- Makes JSA operations more efficient, collaborative, and easy.

- Is compatible with mobiles and tablets.

Some Special Features of the Digitized JSA Tool

A comprehensive JSA software allows more than just identifying and mitigating risks.

It provides;

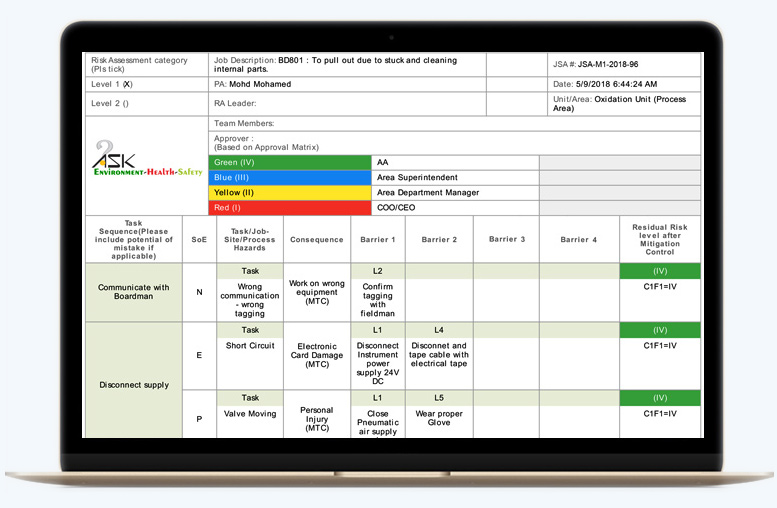

A complete JSA preparation that includes;

- JSA Unique Identifier

- Activity / Job Description

- Identify Hazards

- Risk Assessment

- Control Measures

- Post Risk Assessment

Additional features:

- Submit for approval

- Configurable Risk Matrix

- Approved JSA can be printed and circulated to the working party

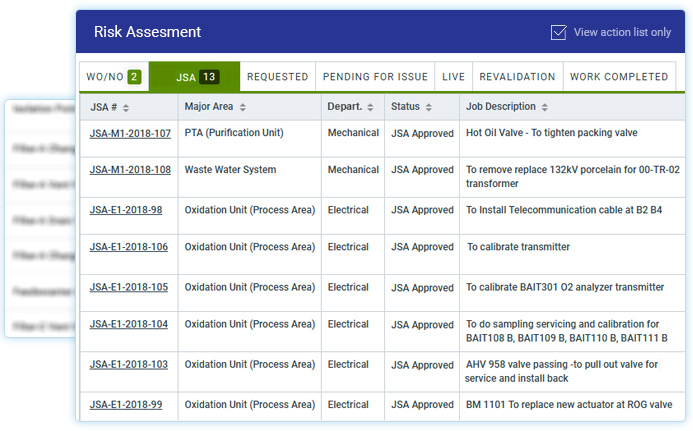

- JSA register is maintained

- Search engine – to search the JSA based on various criteria and content matching

- Hazard and Control Measure Library

The software elevates safety processes, saves time, and ensures continuous improvement for the employees and the organization.

Conclusion

A JSA tool scrutinizes what could go wrong during a task. It gives a microscopic view of the safety issues that could arise during the job. Safety officers must implement the right tools to reduce hazards and incidents through risk control measures and prioritization.

The industries of every sector face various safety challenges every day. Therefore it is the job of the authorities and the stakeholders to be vigilant of potential hazards and incidents while assessing the proper use of tools for doing the same.

If you are still stuck in the age-old JSA method, it is high time to switch to the JSA digital module for standardized and secured safety processes.