Operational Efficiency and digital Permit to Work

Permit to work for managing plant operations, maintenance and associated repairs under the banner of standard safe working conditions is central to modern organizations.

The correlation between cost and time saving by making maintenance and repair processes efficient, responsive and under an established preventive regime offer concrete ROIs than more popular cost-cutting measures. This in light of a PwC article which states that only 30% of such cost-cutting initiatives deliver on their specific targets.

Following passage of text is taken from the reference provided below and the image adaptation following text is reproduced from this chapter as well

“To simplify the objective of defining1 – productivity, best practices and efficiency – a simple equation comes to our rescue:

Productivity = Output/Input

Efficiency = productivity/ productivity of best practice

While we mostly understand productivity and efficiency – best practice (within this context) is defined as “highest productivity achievable”.

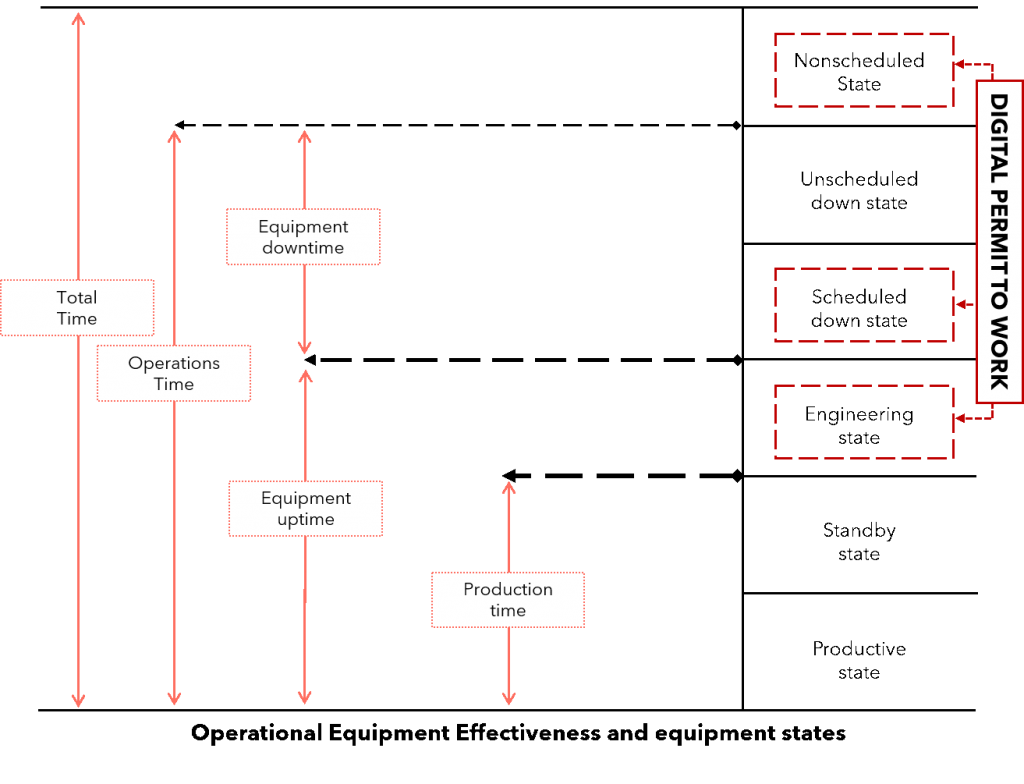

“OEE is a time-based metric to assess productivity and efficiency, particularly for the semiconductor manufacturing industry. The traditional single index metrics of productivity, throughput, and utilization do not allow easy identification of root cause for reduced productivity. The OEE definition describes six standard equipment states”:

| State | Definition |

|---|---|

| Non-scheduled state | Equipment is not scheduled to be used in production, such as unworked shifts, weekends, or holidays (including start-up and shutdown). |

| Unscheduled down state | Equipment is not in a condition to perform its intended function due to unplanned downtime events, e.g., maintenance delay, repair, change of consumable or chemicals, and out-of-spec input. |

| Scheduled down state | Equipment is not available to perform its intended function due to planned downtime events, e.g., production test, preventive maintenance, and setup. |

| Engineering state | Equipment is in a condition to perform its intended function but is operated to conduct engineering experiments, e.g., process engineering, equipment engineering, and software engineering. |

| Standby state | Equipment is in a condition to perform its intended function but is not operated; the standby state includes no operator available (including breaks, lunches, and meetings), no items available (including no items due to lack of available support equipment), and no support tools. |

| Productive state | Equipment is performing its intended functions, e.g., regular production (including loading and unloading of units), work for third parties, rework, and engineering runs done in conjunction with production units. |

Digital permit to work offers the potential to troubleshoot, assist and elevate (3) key states in operational efficiency – engineering, scheduled down state and non-scheduled state.

Here’s a list of features that can aid in the making the following states seamless and easy-to-handle and visible across the stream of operations:

Simplified and Full-Proofed Permit Request Process

Requesting for a work permit made easy while ensuring adherence to all necessary steps vital to carry out the work efficiently and safely (such as risk assessments, detailing of method statement, managing isolations, work-site preparation checks and much more).

Real-Time Permit Tracking & Insights

Accountability Tracking – System auto-logs each and every action taken by the individual personnel with timestamp and remarks. A unique “Area Map” feature gives a bird eye view of all the work being carried out or going to commence shortly across all sites/plants/facilities. Special work statistics to aid in daily permit meetings for planning the permit related activities and getting things done.

Conflict activity map

Leverage the “Area-Map” feature to display comprehensive live permit coverage to identify any overlaps or conflict within work activities for suitable action.

SIMOPS auto-identification and management

Get work conflict alerts whenever a permit is raised for same equipment / system (or-subsystem) or on the same location for which there is already a “Live” permit (on-going work) or another permit requested.

Detailed permit information shown to permit authorities to manage simultaneous operations which have potential overlaps in isolation, energy sources or lock out methods.

With such in-built features in digital PTW – operational efficiency measurement, management and safety become an innate part of the human-machine interaction and lead to safer and more efficient systems of work.

Reference:

1) Adapted from – Lee, Chia-Yen and A. L. Johnson, 2013, “Operational Efficiency”, book chapter edited in: Badiru, A. B. (Editor), Handbook of Industrial and Systems Engineering, 2nd Edition, 17–44, CRC Press.